A devastating explosion at a U.S. Steel facility near Pittsburgh has drawn sharp scrutiny from federal regulators and reignited long-standing concerns about safety practices at the site. Federal regulators have identified safety failures that reportedly exposed workers to an explosion risk at a U.S. steel plant, according to findings released after a detailed investigation into the August incident.

OSHA Investigation Finds Serious Lapses

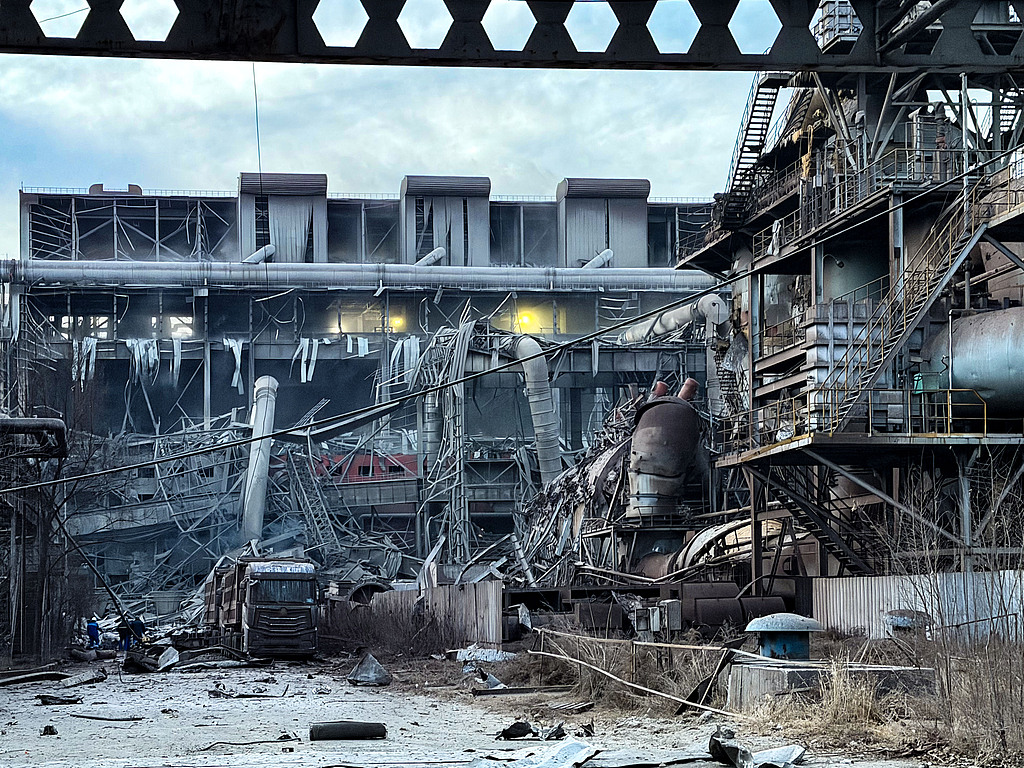

The blast occurred at the Clairton Coke Works, part of U.S. Steel’s Mon Valley Works system. The explosion killed two workers and injured 11 others, including contractors on site. It happened while employees were flushing a gas valve ahead of scheduled maintenance work at the sprawling riverside plant — the largest coke production facility in the Western Hemisphere.

Following the tragedy, the Occupational Safety and Health Administration (OSHA) conducted a comprehensive review. In a 16-page report, the agency concluded that the company’s written procedures, safety practices, and training programs related to equipment maintenance were incomplete, outdated, or insufficient.

According to OSHA, these deficiencies directly contributed to hazardous conditions. When the valve ruptured, combustible coke oven gas was released, creating a highly dangerous environment for workers nearby. Regulators said the gaps in planning and documentation “exposed” employees to an explosion risk.

As a result, OSHA issued 10 citations and imposed fines totaling $118,214. One citation also noted that U.S. Steel failed to provide certain required documentation within the mandated timeframe after the incident.

What Went Wrong?

The company has maintained that the explosion occurred during routine maintenance preparations. However, during an October meeting with local residents, Kurt Barshick, vice president of Mon Valley Works, acknowledged that approximately 3,000 PSI of water pressure became trapped inside a valve rated for just 50 PSI. The excessive pressure caused the valve to crack, allowing gas to flood the area before the explosion.

The U.S. Chemical Safety and Hazard Investigation Board (CSB), which is conducting a parallel investigation, confirmed that 11 additional individuals were hurt in the blast. The CSB’s inquiry remains ongoing.

A Troubled History at Clairton

The August explosion did not occur in isolation. The Clairton plant has faced multiple accidents and safety complaints over the years. Current and former workers have alleged that management shortcomings and insufficient investment have not only weakened workplace safety but also worsened air pollution in surrounding communities.

In addition to safety issues, the facility has been involved in repeated legal disputes with Allegheny County regulators over environmental compliance. Local officials have frequently accused the company of violating air quality standards at the plant.

Company and Union Responses

In a public statement, U.S. Steel said it is reviewing OSHA’s findings but did not indicate whether it agrees with the agency’s conclusions or plans to contest the citations. The company emphasized that safety remains a foundational value and pledged continued cooperation with federal authorities.

OSHA has set deadlines for corrective action and allows companies to challenge findings through an informal conference process.

Meanwhile, the United Steelworkers union expressed appreciation for OSHA’s thorough investigation. District Director Bernie Hall described the incident as a heartbreaking loss and said the union is committed to collaborating with management to implement recommended safety improvements — particularly those related to process safety management systems.

Ongoing Investigation and Next Steps

While OSHA’s report sheds light on procedural shortcomings, the Chemical Safety Board’s investigation continues. Its findings could lead to additional recommendations or regulatory changes aimed at preventing similar disasters in the future.

The tragedy has renewed calls for stronger oversight and better investment in aging industrial infrastructure. For workers and families affected by the blast, accountability and meaningful safety reforms remain urgent priorities.

As regulators push for corrective measures, the spotlight remains firmly on U.S. Steel and whether the company can restore trust at one of the nation’s most historically significant — yet controversial — steelmaking facilities.